Zirconia Foam Ceramic Filter

If your business relies on heavy machinery, construction equipment, or industrial systems, the strength and reliability of forged metal components are critical. Forging delivers unmatched durability and structural integrity, making it the preferred choice across sectors like construction, mining, agriculture, and automotive racing.

Request a Quote

Take the next step to forging your path to success. Request a quote from our team.

Quality Assurance

Ensuring that our processes and products meet international quality and safety requirements.

Feature

| Parameter Category | Specific Parameter | Typical Value / Range | Notes & Explanation |

|---|---|---|---|

| Material & Composition | Main Composition | Zirconia (ZrO₂) | Typically partially stabilized zirconia. |

| Stabilizers | Calcium Oxide (CaO), Yttrium Oxide (Y₂O₃), etc. | Used to stabilize the high-temperature phase. | |

| Physical & Structural Properties | Pore Density (PPI) | 8 ~ 40 PPI | Pores per inch. Higher PPI indicates higher filtration fineness. |

| Porosity | 80% ~ 90% | High porosity is fundamental for efficient filtration. | |

| Bulk Density | 0.8 ~ 1.0 g/cm³ | A lightweight porous material. | |

| Mechanical & Thermal Properties | Compressive Strength (RT) | ≥ 1.5 MPa | Some products can reach ≥1.8 MPa. |

| Maximum Service Temperature | ≤ 1780 °C | Suitable for filtering molten steel >1600°C. | |

| Thermal Shock Resistance | ≥ 6 cycles (1100°C, water quench) | Key for withstanding thermal shock. |

Explore Our Zirconia Foam Ceramic Filter

| DIMENSIONS(MM) | THICKNESS(MM) | POURING RATE(kg/s) | TOTAL CAPACITY (KG) | POROSITY(PPI) | |

| CARBON STEEL | HIGH-ALLOYED STEEL | ||||

| 40*40 | 18,20,22 | 1.5 | 2 | 35 | 10,15,20 |

| 50*50 | 20,22,25 | 2 | 3 | 55 | |

| 60*60 | 22,25 | 3 | 4 | 80 | |

| 100*75 | 22,25 | 6 | 8 | 160 | |

| 150*150 | 25,30,38 | 18 | 23 | 490 | |

| D50 | 22,25 | 1.5 | 2.5 | 50 | |

| D60 | 22,25 | 2 | 3.5 | 70 | |

| D70 | 22,25 | 3 | 4.5 | 90 | |

| D85 | 22,25 | 4.5 | 6 | 130 | |

| D150 | 25,30,38 | 13 | 17 | 400 | |

Frequently Asked Questions

1. What is it, and where is it primarily used?

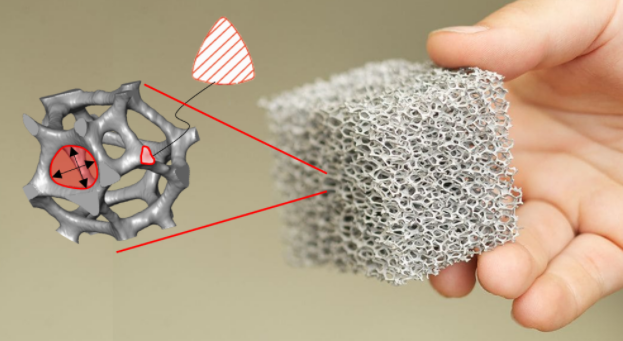

A porous ceramic made of zirconia (ZrO₂) with a 3D interconnected network structure. It is primarily used to filter high-temperature molten steel (e.g., carbon steel, stainless steel, superalloys) to remove slag inclusions and improve casting quality.

2. How to choose the pore size (PPI) and dimensions?

Pore Size (PPI): Common grades are 10, 20, 30 PPI. Higher PPI means finer pores and higher filtration precision but may reduce flow rate; lower PPI offers higher flow capacity. Dimensions: Both square (e.g., 50×50mm to 150×150mm) and round (e.g., D50-D150) are available and customizable. Selection must match the flow rate of the gating system and the required filtration volume.

3. What are its core performance advantages?

High-Temperature Resistance: Withstands up to ~1760°C, suitable for high-end steel casting. High Strength & Thermal Shock Resistance: Can endure the thermal shock from molten metal. Effective Purification: The 3D structure mechanically traps large inclusions and adsorbs fine particles. Flow Regulation: Transforms turbulent metal flow into a steady laminar flow, improving mold filling.

4. Does it require preheating before use? Any key precautions?

Preheating is typically required. Heating to near the molten metal temperature (e.g., using gas or electric heaters for 15-30 minutes) prevents thermal shock cracking and avoids metal splashing from rapid moisture vaporization, ensuring smooth initial filtration.

5. What practical benefits does it offer?

Quality Improvement: Significantly reduces inclusion defects, enhancing surface and internal quality. Yield Increase: Effective filtration lowers scrap rates. Process Optimization: Enables smoother pouring and can simplify gating system design.

Advantages

Featuring extreme temperature resistance up to 1700°C, superior thermal shock stability, and chemical inertness, Zirconia filters efficiently remove micron-sized non-metallic inclusions and convert turbulent flow into stable laminar flow, significantly reducing defects like gas holes and sand inclusions while enhancing the mechanical properties of castings.

Multi-directional applications

As the preferred choice for steel and superalloy purification, these filters are widely utilized in high-precision casting sectors requiring extreme material purity and fatigue strength, including aerospace turbine blades, automotive crankshafts and manifolds, heavy machinery valves, nuclear power components, and medical alloy implants.

Multi-direction Closed-Die Forging Process

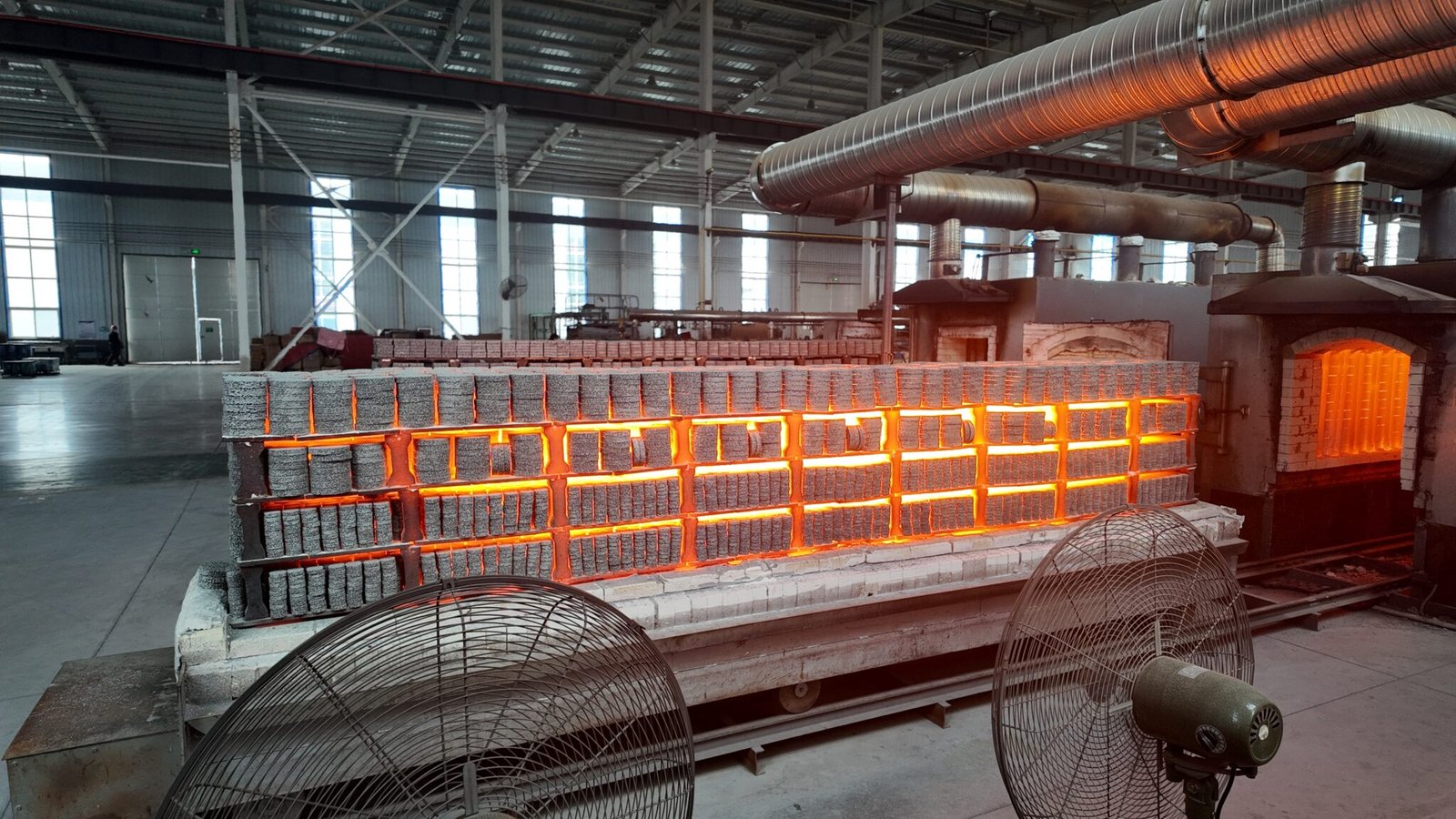

The manufacturing process utilizes the polyurethane foam impregnation method, where zirconia slurry is uniformly coated onto a 3D reticulated carrier; following precise extrusion and controlled drying, the parts are sintered in kilns at over 1700°C, causing the foam carrier to vaporize and the ceramic powder to vitrify into a robust, interconnected skeleton.

These cost-saving advantages, combined with the extra durability, can mean better production rates and higher efficiency for your operations. When you succeed, we know we've succeeded.

Carrier Selection & Pre-treatment

High-quality polyurethane foam with specific porosity and PPI (Pores Per Inch) is selected as the original carrier. The foam is then cut into precise geometric shapes (blocks or discs) according to the final product dimensions to serve as the 3D skeletal framework for ceramic slurry adhesion.

Slurry Impregnation & Coating

A high-viscosity ceramic slurry is prepared by mixing zirconia powder, stabilizers, and binders. The foam carrier is fully submerged in the slurry; mechanical rollers then extrude air and ensure the slurry uniformly and firmly coats the foam fibers while removing excess slurry to maintain open porosity.

Controlled Drying & Shaping

The flashless closed-die design eliminates material waste and the need for trimming. The component is typically formed in one heating cycle and one press stroke, reducing process steps by 50% and significantly lowering costs.

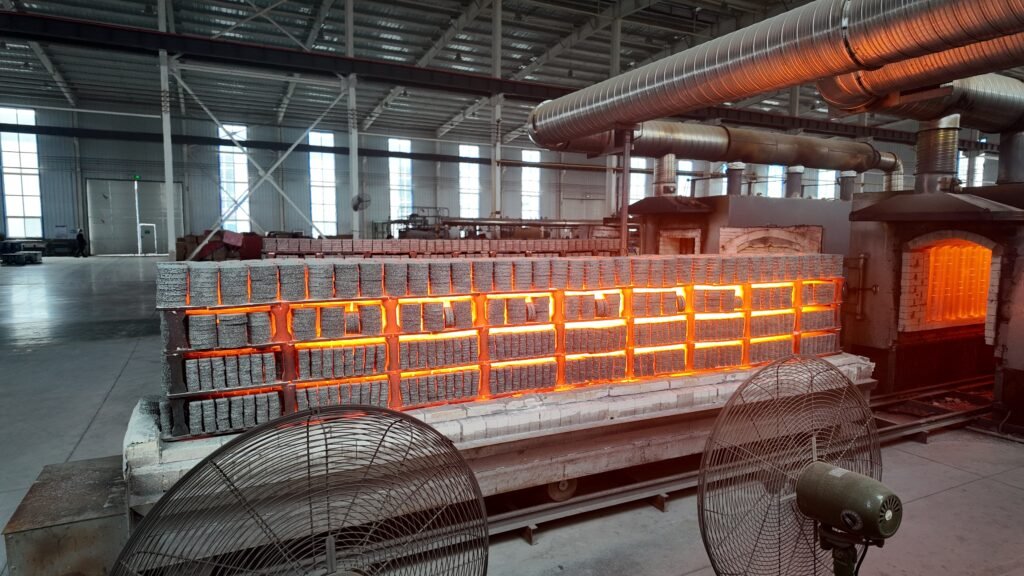

High-Temperature Sintering

This is the most critical stage, where the green bodies are fired in kilns at temperatures exceeding 1700°C. During this process, the polyurethane foam carrier vaporizes completely, and the zirconia powder undergoes physical and chemical reactions to solidify into a high-strength, 3D ceramic grid structure.

High-quality foam ceramic filter

As an innovator in the field of custom multi-directional closed-die forging, Longchao Forging has been dedicated for 30 years to providing customers with the highest quality forged components and attentive service. Therefore, we strive to exceed your expectations and help you find the molten metal filtration solutions that meet your specific needs.

Experience the unique features of Longchao's molten metal filter sheets.

With over 30 years of experience in open-die forging, we combine traditional craftsmanship with modern technology to provide you with molten metal filter plates that perfectly meet your specifications. Our team will work closely with you to ensure we provide the most suitable solution for your application needs.