Since 1900

Our foam ceramic filter products are backed by a century of engineering expertise, paired with tailored services and custom engineering solutions to meet industry-specific filtration demands. By delivering consistent, high-quality filtration, they drive progress in production lines, reduce downtime from contamination issues, and contribute to safer, more sustainable everyday operations across the globe—true to our mission of keeping your world turning.

Our Services

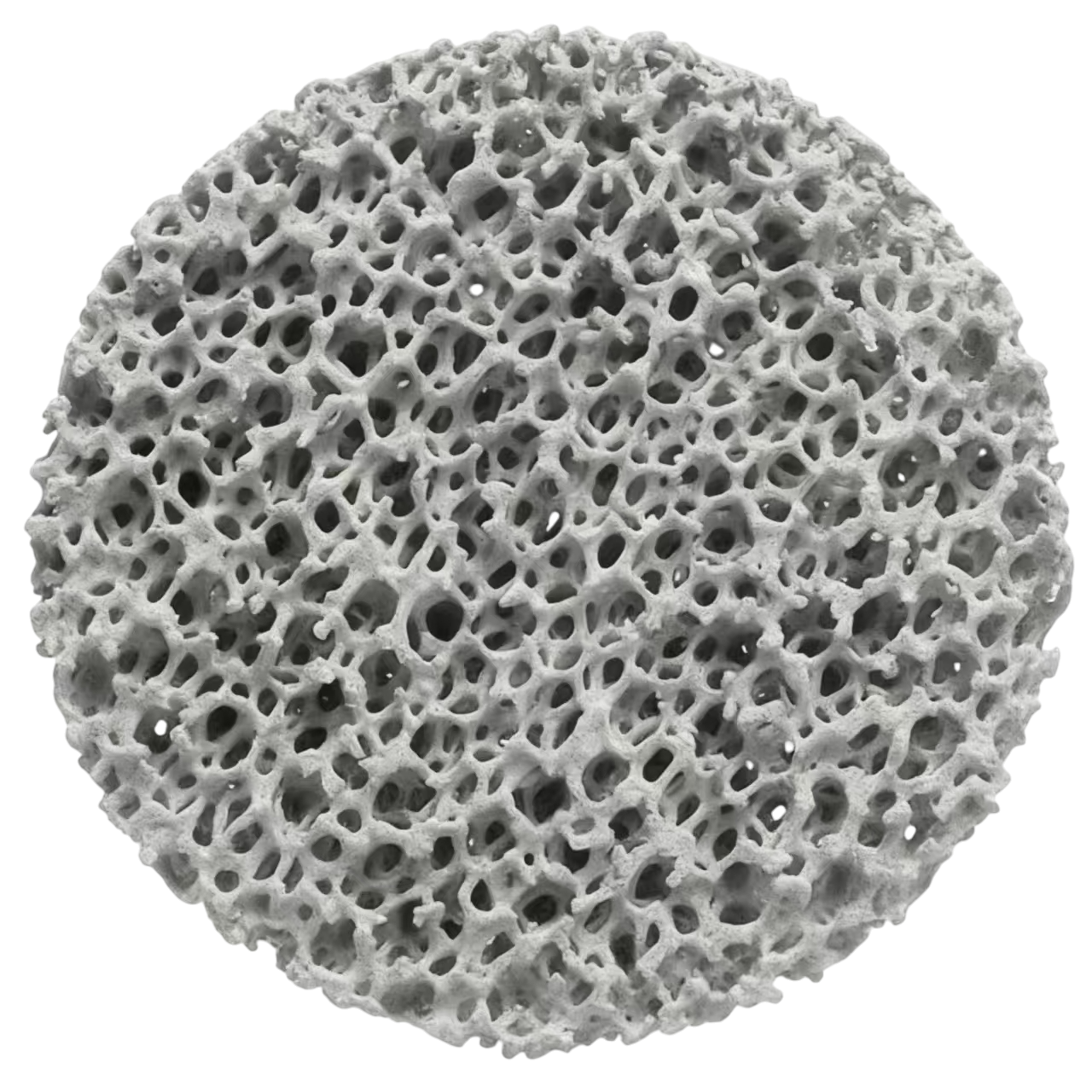

Alumina filter sheet

They exhibit excellent resistance to erosion and corrosion in molten aluminum, and will not chemically react with the molten metal during filtration, thus avoiding secondary contamination.

Silicon carbide filter sheet

Silicon carbide materials have extremely high melting points, allowing them to withstand the scouring and filtration of high-temperature molten metals such as cast iron and cast steel. Their high-temperature strength and chemical stability far exceed those of alumina.

Zirconium oxide filter sheet

It can effectively remove micron-sized non-metallic inclusions (such as oxides and sulfides) from molten steel, significantly reducing the scrap rate of cast steel parts and improving their mechanical properties (strength and toughness).

Leading Manufacturer of Premium Ceramic Foam Filters Since the 1980s

Jinan Longchao Forging Materials Co., Ltd. is a specialized manufacturer of high-end casting auxiliary materials, located in Jinan, China. With a profound history dating back to the 1980s, we have accumulated over 40 years of expertise in the refractory and filtration industry. Today, we are a trusted partner for foundries worldwide, providing advanced solutions to improve metal purity and casting quality…….

Three major product advantages

- High-quality materials and manufacturing processes ensure more stable performance.

- Precision manufacturing control, resulting in greater adaptability.

- Durable design for all scenarios, resulting in lower maintenance costs.

Three major company advantages

- The entire production chain is self-manufactured, ensuring controllable and traceable quality.

- Targeted R&D capabilities, closely aligned with market demands

- Efficient response service reduces cooperation costs

Customized Selection Guide

We offer one-on-one matching services, precisely matching the slurry filter model to the customer's operating conditions and providing usage solutions.

High-efficiency delivery guarantee

Standard models are shipped within 72 hours, non-standard models are delivered within 15 days, and urgent needs can be met by cross-regional sourcing within 48 hours.

Full-cycle after-sales service

4-hour response time for after-sales issues, 24-hour failure analysis report, and support for on-site installation, testing, and maintenance training.

Our Latest Album

We respond to after-sales issues within 24 hours, provide failure analysis reports within 24 hours, and support on-site installation, testing, and maintenance training.