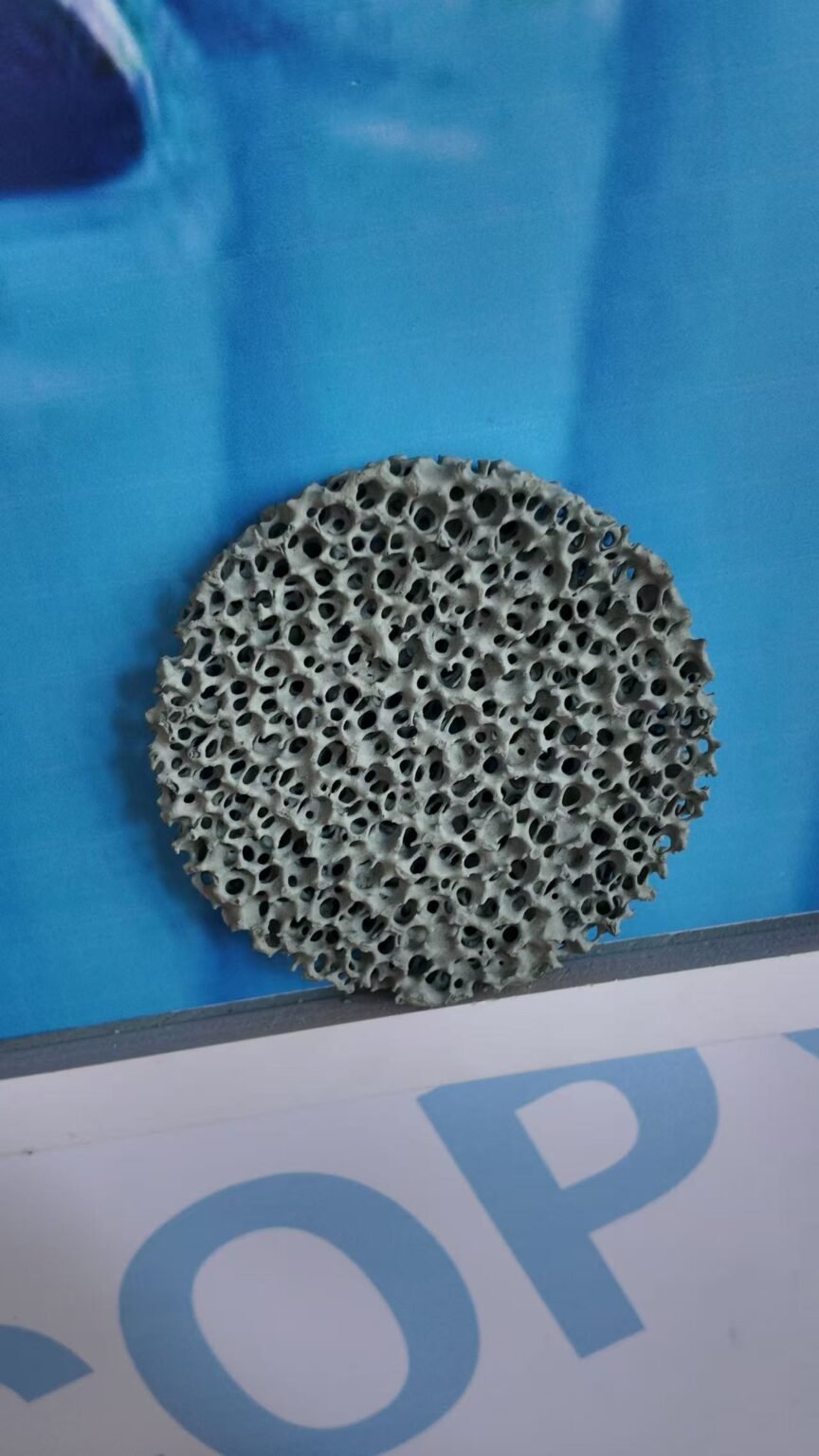

Silicon Carbide Foam Ceramic Filter

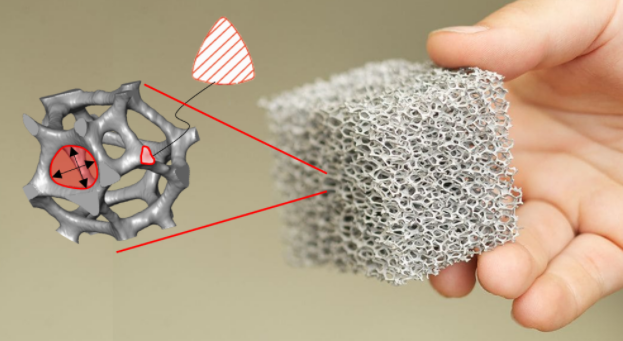

Silicon Carbide (SiC) Foam Ceramic Filter is a porous ceramic product featuring a three-dimensional interconnected network structure. It uses silicon carbide as the primary matrix material and is manufactured by replicating the structure of organic foam through a specialized process followed by high-temperature sintering. This filter combines the excellent properties of SiC ceramic with the high specific surface area of porous materials, making it a critical functional component in fields such as molten metal filtration and high-temperature gas purification.

Request a Quote

Take the next step to forging your path to success. Request a quote from our team.

Quality Assurance

Ensuring that our processes and products meet international quality and safety requirements.

Feature

| Parameter | Typical Range / Value | Notes |

|---|---|---|

| Pore Density | 8 ~ 40 PPI or 10 ~ 30 PPI | Pores Per Inch. Higher PPI indicates finer filtration but also greater resistance to metal flow. |

| Porosity | 80% ~ 90% | The volume percentage of pores within the material. High porosity is fundamental for efficient filtration. |

| Maximum Service Temperature | ≤ 1500°C | Suitable for filtering cast iron (~1400-1500°C) and all copper alloys. Some high-performance products are reported for use at temperatures not lower than 1600°C. |

| Compressive Strength (RT) | ≥ 1.5 MPa | Measures mechanical strength, ensuring the filter can withstand handling, installation, and use. |

| Bulk Density | 0.35 ~ 0.60 g/cm³ | Related to porosity. Much lower than solid ceramics, classifying it as a lightweight porous material. |

| Thermal Shock Resistance | ≥ 2 cycles (1100°C water quench) | The ability to withstand rapid temperature changes without cracking—a critical property for filtering hot metal. |

Explore Our Zirconia Foam Ceramic Filter

| DIMENSIONS(MM) | POURING RATE(kg/s) | Filtering capacity (KG) | ||

| GREY LRON | DUCTILE LRON | GREY LRON | DUCTILE LRON | |

| 40*40*22 | 4 | 3 | 65 | 32 |

| 50*50*22 | 6 | 4 | 100 | 52 |

| 75*50*22 | 9 | 6 | 150 | 75 |

| 75*75*22 | 14 | 9 | 220 | 100 |

| 100*50*22 | 12 | 8 | 200 | 100 |

| 100*75*22 | 18 | 12 | 300 | 150 |

| 100*100*22 | 24 | 16 | 400 | 200 |

| 150*100*22 | 36 | 24 | 600 | 300 |

| 150*150*22 | 50 | 36 | 900 | 450 |

| 170*150*32 | 62 | 42 | 1020 | 510 |

| 200*170*32 | 84 | 56 | 1400 | 700 |

| D50*22 | 5 | 4 | 80 | 40 |

| D60*22 | 6 | 5 | 110 | 55 |

| D80*22 | 12 | 8 | 200 | 100 |

| D90*22 | 16 | 10 | 240 | 120 |

| D125*25 | 28 | 18 | 440 | 220 |

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

1. What is a Silicon Carbide Foam Ceramic Filter?

A porous ceramic structure made primarily of silicon carbide (SiC), featuring a three-dimensional, interconnected open-cell network (like a sponge) used for filtration.

2. What are its core advantages?

It combines excellent thermal shock resistance, high-temperature stability (up to ~1500-1600°C), good chemical inertness against molten metals (especially iron and copper alloys), effective deep-bed filtration, and a favorable strength-to-weight ratio due to its porous structure.

3. How do I choose the correct PPI (pores per inch)?

Lower PPI (e.g., 10-15): Offers lower flow resistance, suitable for applications requiring high flow rates or filtering larger particles. Higher PPI (e.g., 20-30): Provides finer filtration for capturing smaller inclusions, used when superior metal purity is critical. Selection involves balancing flow needs with purity requirements.

4. What metals is it primarily used for?

It is the standard and most cost-effective choice for filtering ferrous metals with lower melting points (cast iron, ductile iron) and all copper-based alloys (brass, bronze). It is generally not recommended for high-alloy steels, which require higher-temperature filters like zirconia.

5. Does it require preheating before use?

Yes, preheating is essential. Typically to around 800-1000°C to prevent thermal shock cracking and to avoid moisture-related issues (steam generation, metal splashing) when contacting the molten metal, ensuring both filter integrity and casting safety.

Advantages

The superior performance of SiC foam filters stems from the intrinsic properties of silicon carbide and its unique foam architecture. Firstly, it exhibits exceptional thermal and mechanical properties. The covalent bonding nature of SiC allows it to withstand temperatures up to approximately 1560°C, offering excellent high-temperature strength and remarkable thermal shock resistance. This enables it to endure thermal stress upon contact with molten metal without cracking. Secondly, it boasts outstanding chemical stability and filtration efficiency. It demonstrates high corrosion resistance against molten metals and slags. Its three-dimensional network structure not only mechanically traps large inclusions but also effectively removes micron-sized non-metallic inclusions through deep-bed adsorption mechanisms, significantly purifying the melt.

Multi-directional applications

The application of SiC foam ceramic filters has significantly broadened. In metal casting, they are essential for filtering cast iron, ductile iron, and copper alloys, reducing defects and improving mechanical properties. They are particularly effective for high-performance alloys like FeSiB soft magnetic alloys. Beyond foundries, their high-temperature resistance and high surface area make them valuable in high-temperature gas purification (e.g., diesel exhaust) and as catalyst supports or filters in chemical processes. The product forms have also diversified from simple blocks to tubes and honeycomb structures for various industrial needs.

Multi-direction Closed-Die Forging Process

This manufacturing process utilizes a polyurethane foam impregnation method, uniformly coating a silicon carbide slurry onto a three-dimensional network carrier. After precise extrusion and controlled drying, the component is sintered in a furnace at over 1700°C, causing the foam carrier to vaporize and the ceramic powder to vitrify, forming a robust, interconnected skeletal structure.

These cost-saving advantages, combined with the extra durability, can mean better production rates and higher efficiency for your operations. When you succeed, we know we've succeeded.

Carrier Selection & Pre-treatment

High-quality polyurethane foam with specific porosity and PPI (Pores Per Inch) is selected as the original carrier. The foam is then cut into precise geometric shapes (blocks or discs) according to the final product dimensions to serve as the 3D skeletal framework for ceramic slurry adhesion.

Slurry Impregnation & Coating

A high-viscosity ceramic slurry is prepared by mixing zirconia powder, stabilizers, and binders. The foam carrier is fully submerged in the slurry; mechanical rollers then extrude air and ensure the slurry uniformly and firmly coats the foam fibers while removing excess slurry to maintain open porosity.

Controlled Drying & Shaping

The flashless closed-die design eliminates material waste and the need for trimming. The component is typically formed in one heating cycle and one press stroke, reducing process steps by 50% and significantly lowering costs.

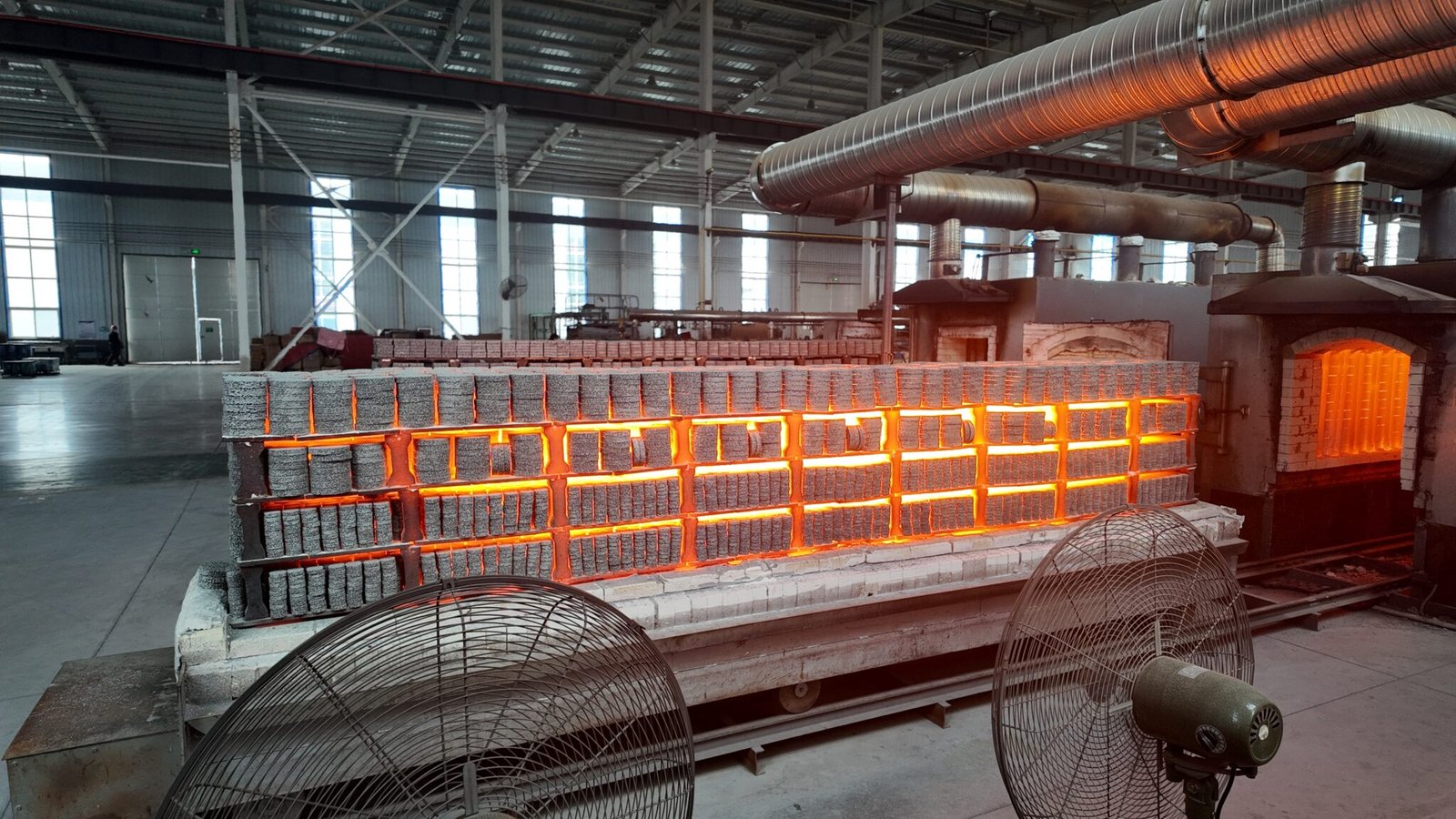

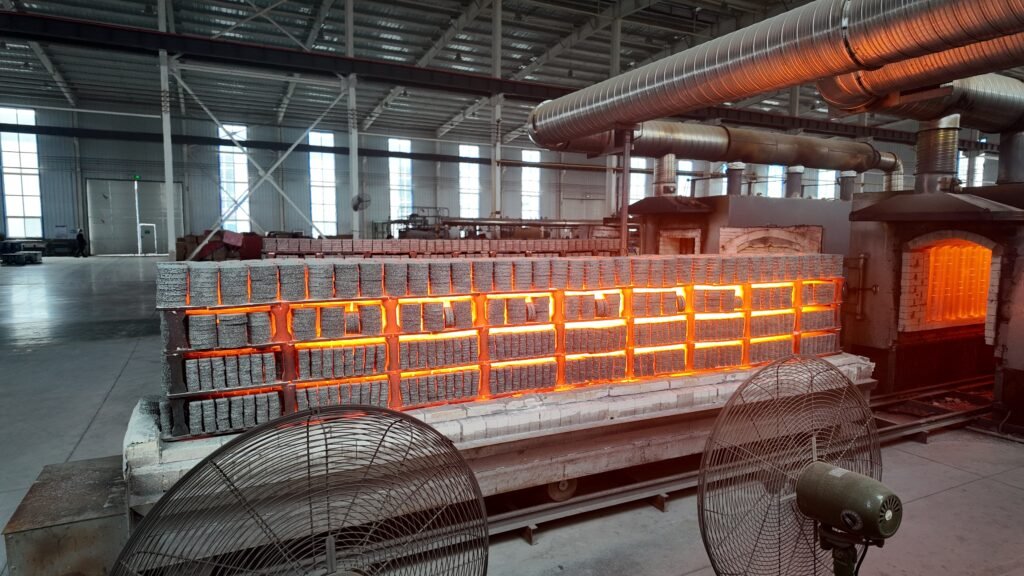

High-Temperature Sintering

This is the most critical stage, where the green bodies are fired in kilns at temperatures exceeding 1700°C. During this process, the polyurethane foam carrier vaporizes completely, and the zirconia powder undergoes physical and chemical reactions to solidify into a high-strength, 3D ceramic grid structure.

High-quality foam ceramic filter

As an innovator in the field of custom multi-directional closed-die forging, Longchao Forging has been dedicated for 30 years to providing customers with the highest quality forged components and attentive service. Therefore, we strive to exceed your expectations and help you find the molten metal filtration solutions that meet your specific needs.

Experience the unique features of Longchao's molten metal filter sheets.

With over 30 years of experience in open-die forging, we combine traditional craftsmanship with modern technology to provide you with molten metal filter plates that perfectly meet your specifications. Our team will work closely with you to ensure we provide the most suitable solution for your application needs.