Our Story

Create each product with a professional attitude and professional techniques

With a philosophy of “unchanged focus” for three decades, we understand that reliability is the most important factor in manufacturing. We don’t just provide a product; we provide a solution to improve your casting quality and global competitiveness.

30

360K

Satisfied clients around the World

642

Projects have been completed in 18 countries

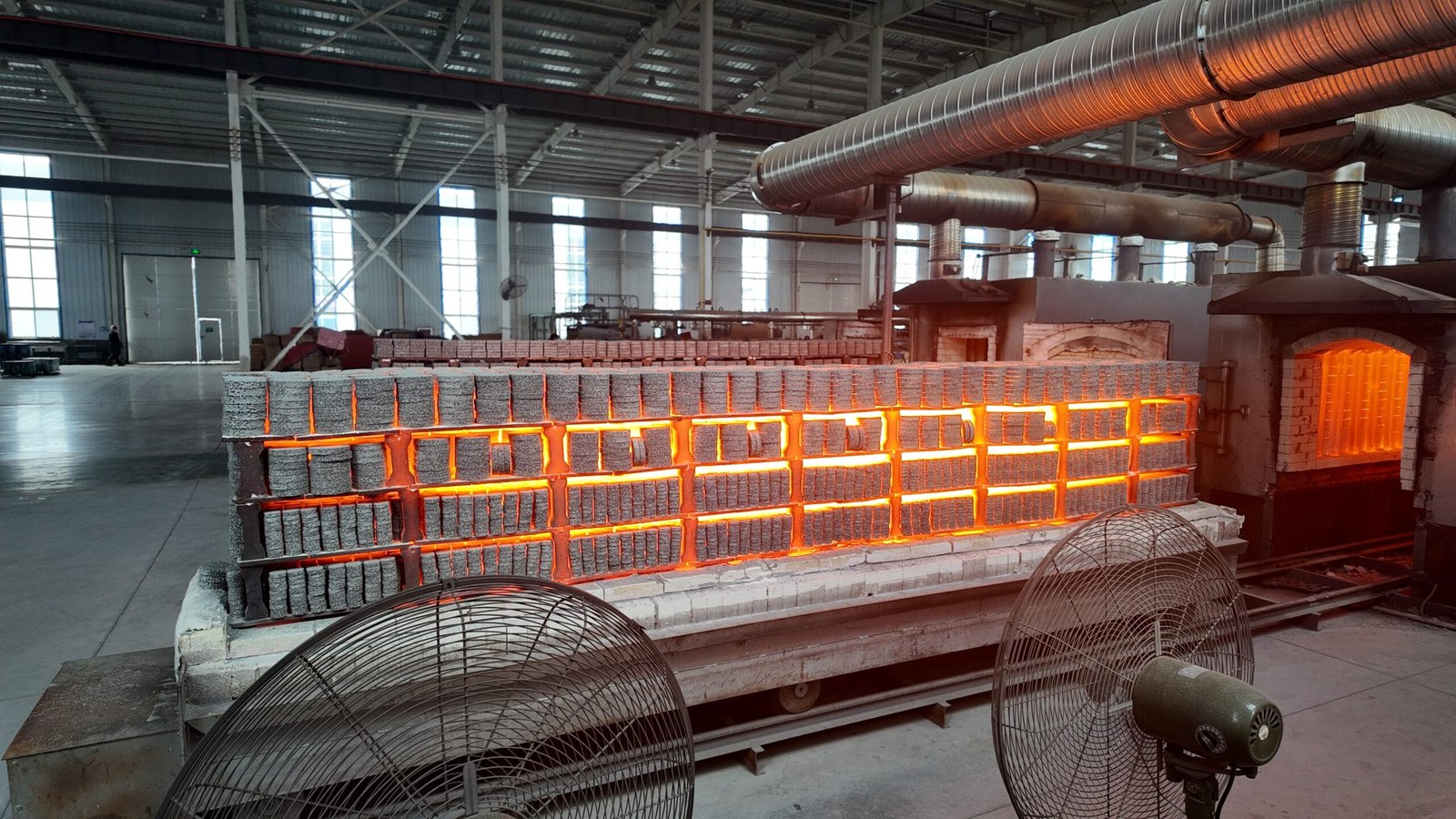

Our Process

Steps to Your Dream Outdoor Space

1. Consult

We begin with a personalized consultation to capture your vision and needs.

2. Design

Our experts will develop a detailed plan encompassing all aspects of metal smelting and filtration for your approval.

3. Execute

Our highly skilled team will produce all the products you purchase with precision and meticulous work.

The Goal

Our Mission

To empower the global foundry industry by engineering high-precision Silicon Carbide (SiC) ceramic foam filters that redefine casting quality. We are dedicated to helping our partners minimize turbulence, eliminate impurities, and achieve zero-defect production through relentless material innovation and rigorous quality standards. At Longchao, we don’t just provide filters; we provide the foundation for structural integrity and manufacturing excellence.

The Outlook

Our Vission

To become a globally recognized leader and a trusted benchmark in the field of advanced metallurgical filtration. We strive to lead the industry’s transition toward more sustainable and efficient casting processes, envisioning a future where “Longchao Filtration” is synonymous with peak performance, technological breakthrough, and environmental responsibility in the global forging and casting landscape.

Giving Back

Industry Engagement & Strategic Partnerships

At Longchao, we believe that progress is born from collaboration. We don’t just supply filters; we immerse ourselves in the global foundry ecosystem to stay at the forefront of metallurgical technology.

Global Foundry Collaboration: We actively participate in international trade fairs and technical symposiums (such as MetalChina and GIFA), engaging with leading engineers to exchange insights on the future of molten metal filtration.

Joint R&D Initiatives: We partner with metallurgical research institutes and high-end foundries to develop customized Silicon Carbide (SiC) solutions that address specific casting challenges, such as extreme temperature fluctuations and complex alloy compositions.

The Feedback Loop: Customer-Centric Innovation

Your performance data is our most valuable asset. We have built a robust “Feedback-to-Innovation” loop that ensures our products evolve alongside your manufacturing needs.

Real-Time Performance Monitoring: We encourage our partners to provide detailed performance reports on filter efficiency, flow rates, and inclusion-trapping results. This data is directly integrated into our quality control system.

On-Site Technical Audits: Our expert engineers are available for on-site visits to observe the casting process firsthand, allowing us to troubleshoot issues and fine-tune our material formulations based on real-world feedback.

Rapid Response System: We maintain a dedicated 24/7 technical support channel. Whether it’s a suggestion for a new pore size or a report on thermal shock resistance, every piece of feedback is reviewed by our R&D team within 48 hours.